Our models consider crucial factors like cell density, osmolarity, gas exchange, carbon sources, metabolite accumulation, toxins, byproducts and more. This comprehensive approach ensures optimal bioprocess performance, while effectively addressing challenges related to cell growth and environmental conditions.

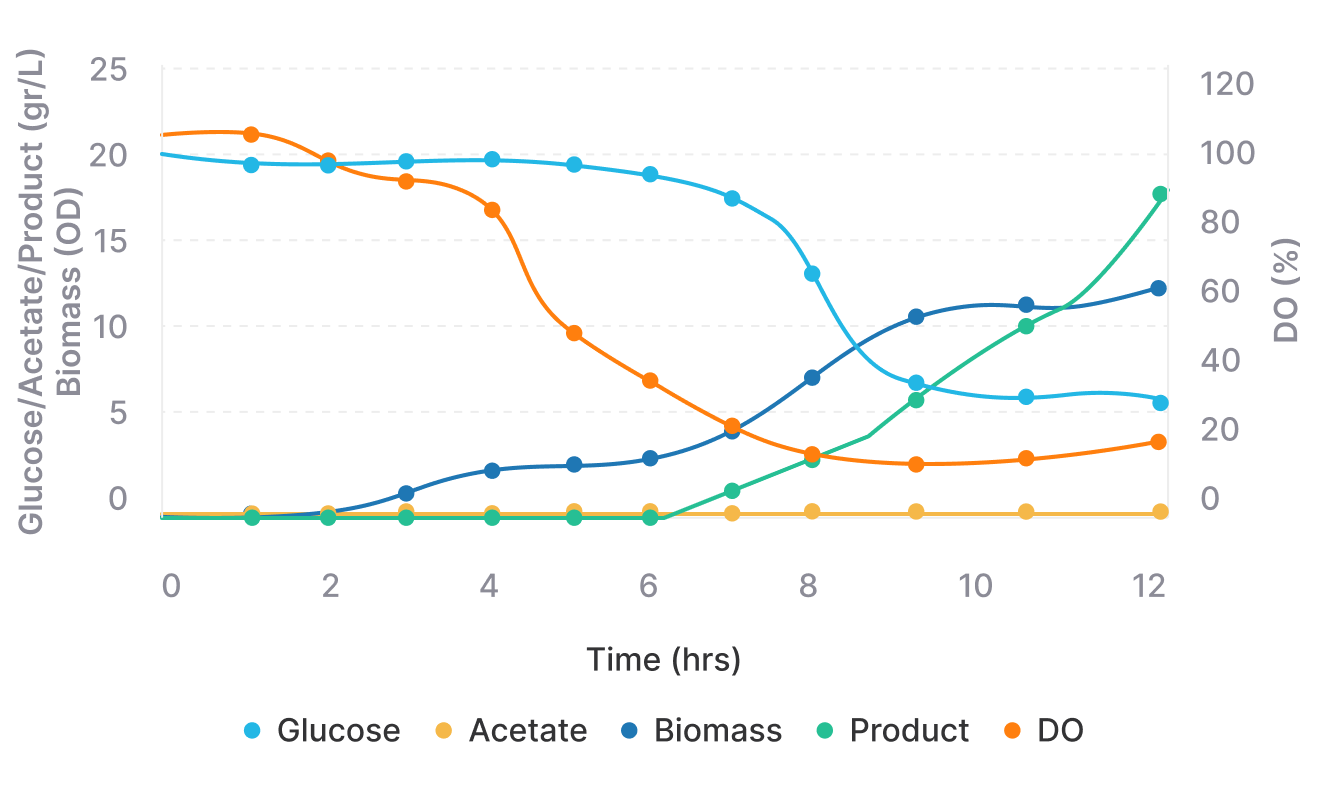

Our models take into account the rate at which carbon sources are consumed, as well as the rate at which metabolites are produced. These factors are essential for simulating and predicting the cellular processes involved in converting nutrients into energy, biomass, and various products.

Integrating soft sensors into our models enriches our understanding of the underlying processes, which allows us to significantly enhance optimization efforts. These tools enable us to collect and analyze data that may not be directly measurable, offering insights into the dynamics of bioprocesses and supporting more informed decision-making.

Effective control of gene expression is essential for optimizing productivity in bioprocessing, particularly in the production of recombinant proteins. Different feeding strategies impact the expression of relevant genes, influencing process efficiency. The Algocell platform uses hybrid models to incorporate gene expression into the regulation and creation of feeding strategies, fine-tuning the process in real-time to maximize productivity.

Our models carefully consider various factors that could potentially compromise the quality and safety of the final product. These factors include cell density, cell viability, and the concentration of impurities, which can negatively affect product integrity. By analyzing these elements, we insure that our models help maintain high standards for both product quality and safety, ultimately leading to more reliable and effective outcomes.

Our models are designed to fit within the capabilities of your existing equipment, including pump capacity, cooling capabilities, volume constraints, and pressure differentials. By tailoring our solutions to your specific engineering requirements, we optimize bioprocess performance within the practical constraints of your setup, ensuring high product quality, regulatory compliance, and improved overall efficiency.

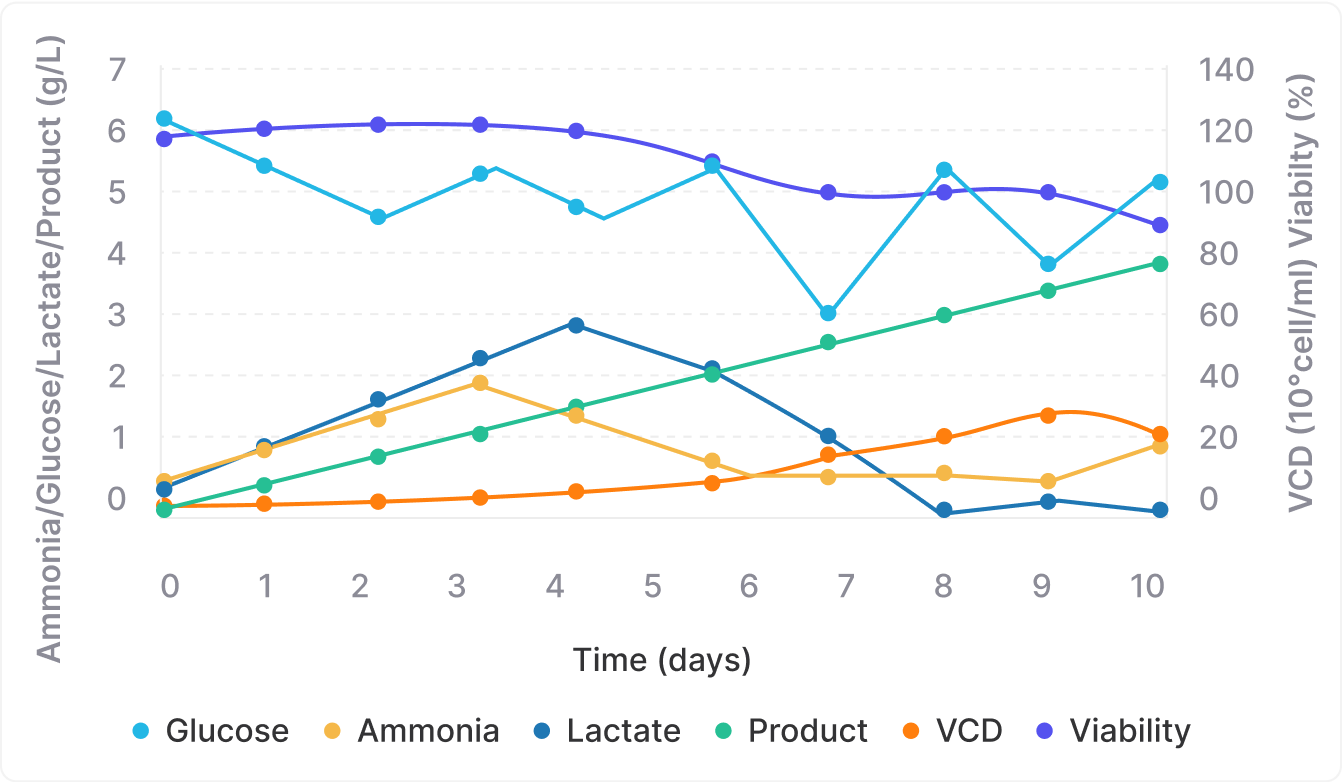

In fed-batch mammalian cell cultures, the feeding strategy is essential for sustaining an environment that promotes optimal cell growth and maximizes protein yield. Precise control of nutrient feeds:

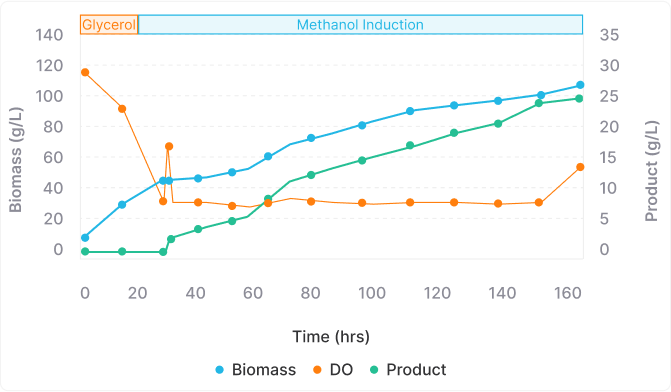

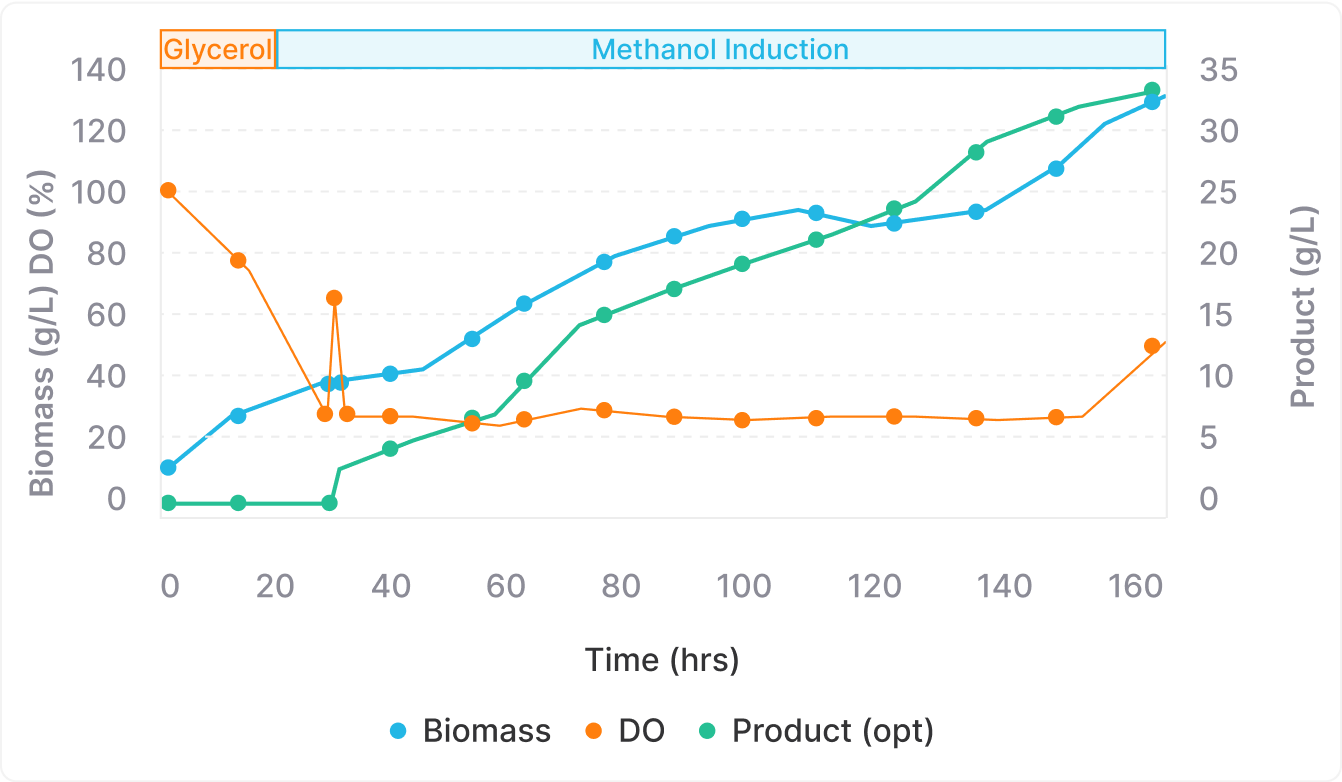

In fed-batch Pichia pastoris processes, carefully balancing glycerol for cell growth and methanol for protein induction is crucial to achieving maximum production efficiency. Glycerol supports strong cell growth, while methanol triggers protein expression through the specific promoter. Properly balancing glycerol and methanol feeds:

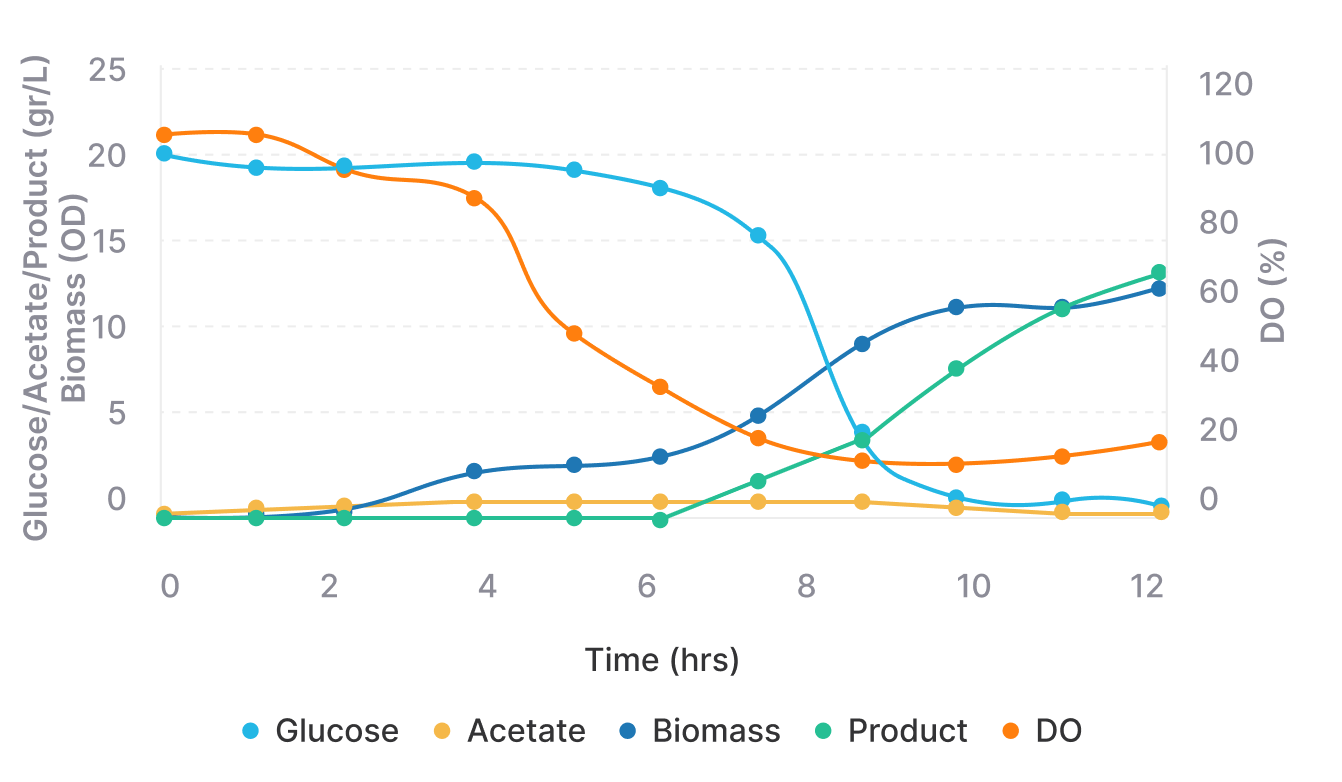

In fed-batch Escherichia coli processes, precise glucose management is crucial to preventing nutrient depletion and avoiding the accumulation of toxic byproducts. Controlled glucose feeding:

Welcome to Algocell (“we,” “our,” or “us”). By accessing or using our website www.algocel.ai, you agree to comply with and be bound by the following Terms of Use. Please read these terms carefully. If you do not agree with them, you should not use this website.

To the maximum extent permitted by law, Algocell and its affiliates shall not be liable for any damages, including indirect, incidental, consequential, or punitive damages, arising out of your use or inability to use this website.

Our website may contain links to third-party websites. We do not control or endorse these external sites and are not responsible for their content or privacy practices.

If you have any questions regarding these Terms of Use, please contact us:

Algocell

Email: contact@algocel.ai

Website: www.algocel.ai

Algocell (“we,” “our,” or “us”) respects your privacy and is committed to protecting your personal data. This Privacy Policy explains how we collect, use, disclose, and safeguard your information when you visit our website www.algocel.ai.

We may collect the following types of personal data:

We use your personal data to:

We process personal data under the following legal bases:

We do not sell your personal data. We may share information with:

We retain your personal data only as long as necessary for the purposes set out in this policy, unless a longer retention period is required by law.

You have the right to:

Algocell uses cookies and similar technologies to improve your browsing experience and analyze site traffic. You can control or disable cookies through your browser settings. For more information, see our [Cookie Policy].

We implement appropriate technical and organizational measures to protect your personal data from unauthorized access, alteration, disclosure, or destruction.

If personal data is transferred outside the European Economic Area (EEA), we ensure adequate safeguards are in place, such as Standard Contractual Clauses approved by the European Commission.

If you have any questions about this Privacy Policy or your data, please contact us at:

Algocell

Email: contact@algocel.ai

Website: www.algocel.ai